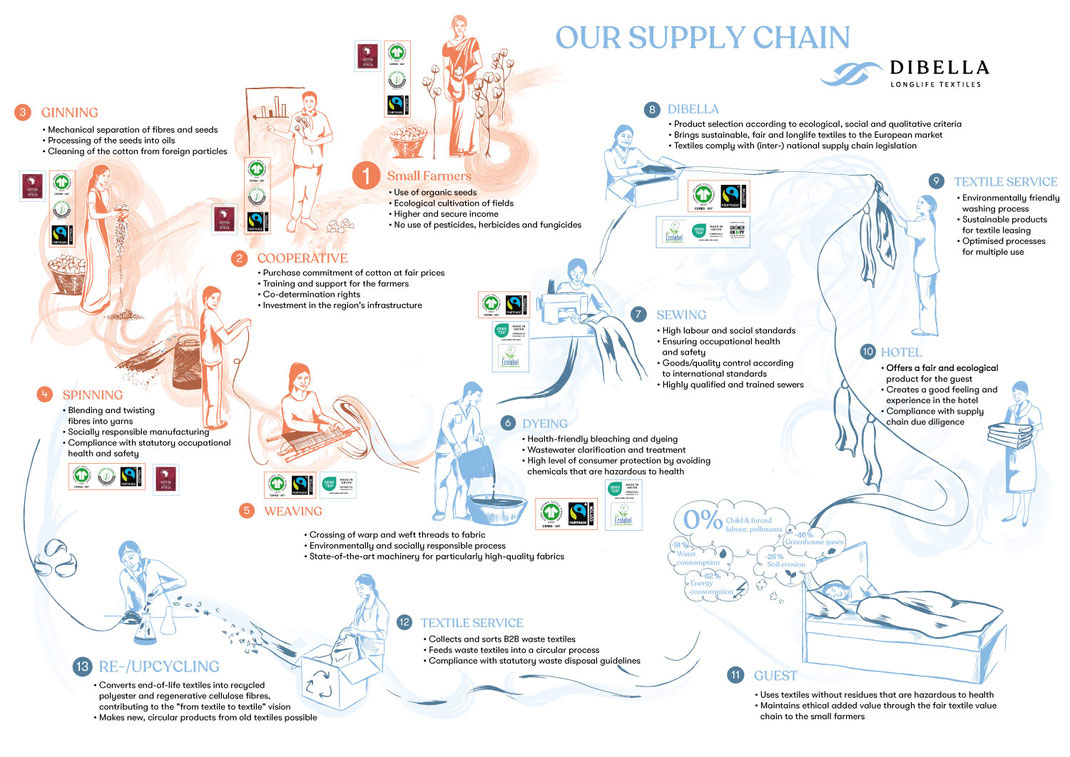

Practiced sustainability along the entire value-added process - already standard at Dibella

The textile value chain is long and full of challenges. Dibella already assumes responsibility here in the standard and is committed to human rights, environmental protection and health. Sustainability that benefits everyone involved. In the case of Longlife Textiles, the high criteria of MADE IN GREEN/Green Button apply to almost all articles (exact details of the respective certificates can be found on the respective products). For sustainable raw materials, we implement Cotton made in Africa-verified cotton in our supply chain, supporting socially and environmentally sustainable cotton production in Africa.

Our goal is to constantly increase this share.

1. Micro farmers

Dibella is proud to partner with the Cotton made in Africa (CmiA) initiative, an internationally recognized standard for sustainable cotton grown by smallholder African farmers. CmiA-verified cotton has a significantly lower environmental impact than conventional cotton and supports village communities in Africa.

2. Cooperative

The cooperative, comparable to a cooperative, supports the micro-farmers, for example by guaranteeing the purchase of the cotton harvest. The "umbrella" of the cooperative offers security and other advantages:

- Purchase of cotton at fair prices

- Training and support for the farmers

- Investment in infrastructure projects in the region

3. Ginning

The so-called "ginning" extracts the seed from the harvested plants. This seed can be used again by the farmer and does not have to be purchased anew. A resource-saving process that brings further benefits:

- Mechanical separation of fibers and seeds

- Ginning without hazardous chemicals

- Obtaining new organic seed for the micro-farmers

4. Spinning

The production facilities for further processing of the organic cotton are all Fairtrade certified and stand out for their compliance with the strict specifications:

- Socially responsible manufacturing

- Neither child nor forced labor

- Compliance with legal labor protection

5. Weaving

This production step is also based on the responsible treatment of employees and the environment:

- High-quality woven fabrics

- Quality assurance

- Environmentally and socially responsible process

6. Dyeing

This is where the fabrics are given their desired appearance. During the bleaching and dyeing processes, our partners reliably and verifiably comply with the relevant guidelines:

- Bleaching and dyeing that is harmless to health

- Clarification and treatment of waste water

- Consideration of occupational safety and environmental protection

- High level of consumer protection by not using chemicals that are hazardous to health

7. Sewing

The seamstresses and sewers who process the fabrics work under humane conditions. All employees receive recognition and appreciation for their performance:

- Fair working conditions

- Attention to the health of the seamstresses and sewers

- Occupational safety standards

- Fire and building protection

8. Dibella

Dibella presents the entire textile value chain transparently - starting with product development - and thus guarantees significant advantages, such as:

- Product selection according to environmental, social and quality criteria.

- Brings sustainable, fair and durable textiles to the European market

- Provides opportunities for differentiation through a clear commitment to sustainability

- Supports with explanatory marketing material from the laundry service to the hotel guest

9. Industrial laundry

The transparent supply chain offers advantages to industrial laundries in terms of textile properties, as well as many opportunities for communication:

- Environmentally friendly washing process

- Sustainable products for textile leasing

- Laundry leasing supports multiple use in the cycle

10. Hotel

Beyond the pure laundry service, the hotelier receives a sustainable added value. By using the certified textile concept, he can clearly distinguish himself from his competitors and offer his guests a special product and the associated good feeling:

- Provides fair and ecological product for the guest.

- Creates a good feeling and experience in the hotel

11. Guest

Discreetly, but clearly, the use of sustainably and fairly produced textiles is pointed out. The guest can thus directly experience the added value and will associate the hotel stay with a particularly good feeling, gladly come back and recommend the hotel.

- Uses textiles without residues that are hazardous to health

- Obtains ethical added value via the fair textile value chain down to the smallest farmer

12. Textile Service

- Collects and sorts B2B used textiles

- Feeds used textiles into a circular process

- Compliance with legal waste disposal guidelines

13. Re- / Upcycling

- Converts old textiles into recycled polyester and regenerated cellulose fibres, thus contributing to the vision of "from textile to textile”

- Makes new, circular products from old textiles possible