Dibella complaint management for strategic suppliers.

Grievance mechanism

We take responsibility for people involved in the production of our textiles. To this end, we work exclusively with suppliers

who have proven to meet our high standards in terms of human rights, environmental protection and health.

In addition to recognized certifications, personal exchange with our suppliers is important to us. Only those who know "where the shoe pinches" can take action.

It is therefore a core concern of ours to offer employees the opportunity to contact us directly in the event of any complaints:

Contact person:

Mrs Michaela Gnass

CSR Manager

email: gnass@dibella.de

phone: +49 (0) 2871 2198-63

Processes

Procedure

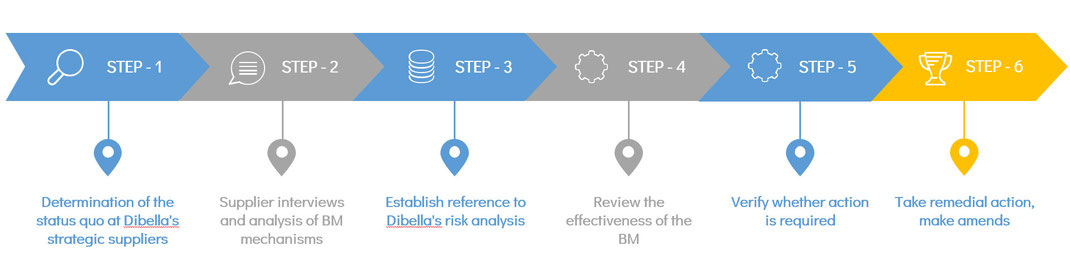

A) Dibella complaint management for strategic suppliers.

Data collection structured by

- Country

- Certifications (GOTS,..)

- Complaints received

- Solutions found

- Associations/trade unions

- Complaint boxes

- Integrated Complaints Policy/Documentation

Outcome: Integrated grievance mechanisms/communication channels from all strategic suppliers are in place by query. All strategic suppliers have their own complaint channels.

B) Dibella analyses complaint mechanisms/communication channels at strategic suppliers Analysis

1. establish reference to Dibella's risk analysis

Outcome: Country-related and already prioritised risks are related to the respective complaint mechanism of the strategic supplier.

C) Dibella reviews grievance mechanisms/communication channels for effectiveness.

Verify effectiveness through

- Audits, certificates

- through Dibella's own projects*

- Verification of implemented measures through "on-site visit"/checklist

* = Implementation of a project "Inflation compensation for employees of a supplier" in spring 2024. A detailed report will follow.

Outcome: Complaint mechanisms/communication channels are tested and assessed for effectiveness.

D) Dibella derives further measures if necessary

Check whether further measures are necessary

- Initiate CAP

- See C) Check, re-run effectiveness

E) Dibella schafft gffs. Abhilfe/Wiedergutmachung

Remedy and access to redress

- Dibella creates organisational and personnel conditions.

These have been set up and corresponding responsibilities have been defined with the following contact persons:

Purchasing Manager: Mr. Simon Bartholomes

CSR Manager: Ms. Michaela Gnass - Question: Have any remedial action been taken/reparations made in the last 12 months?

No. We are not aware of any specific case of causation in which Dibella has taken remedial action or made amends.

Dibella acts according to the "precautionary" principle. Dibella initiates and finances projects through the established GoodTextiles Foundation to promote socially and ecologically positive effects.

For example: training centre for organic Fairtrade farmers, school projects to promote education, compensation of CO2 emissions in the Dibella forest, etc. (further information at: www.goodtextiles.org)

In the event of a remedy/recovery, the following process shall apply:

To 1) Awareness of the demonstrably caused damage

To 2) Exchange/dialogue with affected parties (travel or in writing)

To 3) Draw up documentation (list of complaints)

To 4) Stakeholders and Dibella work out joint remedial measures (form and amount)

To 5) Check whether those affected agree with the result. If necessary, initiate CAP.

Dibella is proactively working to further develop social dialogue with and among its supply partners.

Receipt of a complaint 2022/2023:

During the visit of a Pakistani supplier, employees complained about uncomfortable chairs in the sewing room. In dialog with the 80 people concerned, it was agreed to provide a selection of alternative chairs. After a test phase, the employees opted for a model with an upholstered backrest.

Those affected are satisfied with the remedy provided and have given us positive feedback.

Receipt of two complaints in 2024

In spring 2024, we received a complaint by email from two former employees of a supplier. The employees told us that they had been dismissed because of reduced capacities. At the same time, new staff would have been recruited. Dibella arranged a mediation meeting with the supplier. One employee attended the meeting, one did not.

One employee accepted a new position in another company and thanked us for our support. One employee did not provide any further feedback despite repeated contact from us.